First a note: I can't send private messages so you can ask me stuff but I have to use the forum itself to answer...

I continue my work with the injectors, we gonna use old-school injection either by using a line-pump (A, MW or P) or a non-electronic version of a rotor (VE) found on Ford Transit 2.5 and Land Rover 2.5. (you can use guides about VW pumps but due to smaller engines they have smaller plunger in the pump so it's better to start with something big right away ;-)

In this forum there is plenty info on how to ruin a VE rotor pump so maybe I skip that part, if I am correct

Pugmarshall is doing that so maybe he is willing to add the pump part?

So the injectors, as wrote before I am using Land Rover 300tdi injectors, they are cheap and easy to work with and in stock setup they can handle up to 180cc (per 1000 injections) of fuel so that should be good enough for way over 200BPH.

But 200BPH is for sissies right? ;-)

We want to inject over 300cc of fuel so we need bigger nozzles, for that we choose DLLA144P144 which are used on Scania and MAN trucks, the main issue when choosing nozzles are the spraying angle (144 means 144 degree, original are 135 I believe so not to much difference) and the injector angle (the holes in the nozzle should reflect the correct injector angle else we will spray holes in the head or pistons the same way a water cutter does and believe me that will happen) unfortunately that angle is nowhere to be seen in the docs so that is trial and error...

Another thing according to nozzles is how to rotate them when mounting, these nozzles have 5 holes in it and since the injector is mounted under an angle you have to watch the position of the holes and rotate the injector when mounting to match it all up.

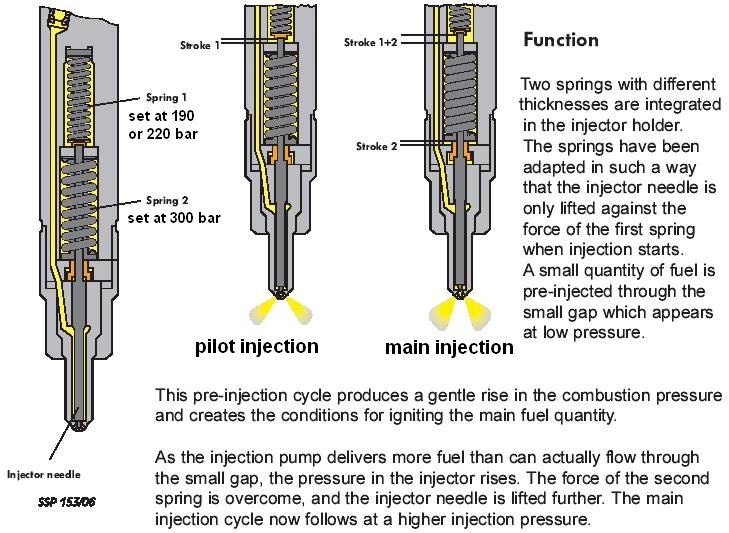

There are 2 ways to get a working injector, we can choose to either make a one-shot injector set at say 320bar that makes a hell of a bang but has some troubles running idle or we can follow the 300tdi injectors 2-stage injection setup:

p.s. if you want a single shot setup you can use the bushing from a DW10 Siemens piezo injector instead of the LaRo one, needs some mods to the rod use for the first spring so both the first and second spring are used at the same time but I won't describe that so you have some room for your own skills... ;-)

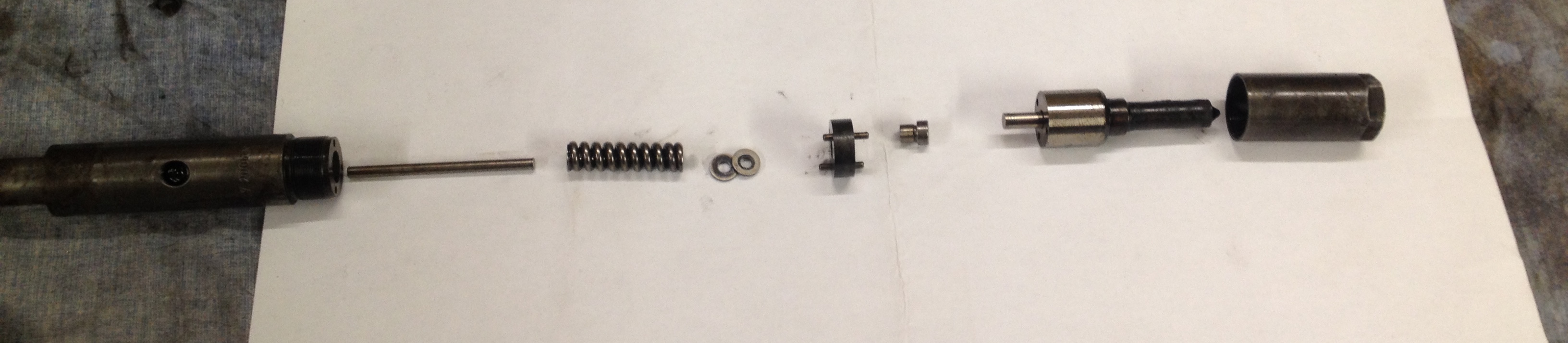

Over here a 300tdi injector in pieces:

Over here we see the 300tdi nozzle, the needle in the nozzle is the same hight as the nozzle so the bushing is limiting the needle movement.

The chamber in the inner part part of the bushing is 0,03mm and the part itself can move 0,27mm in the bushing so we have 0,03mm lift@200bar and a total of 0,3mm@300bar.

Over here our Scania nozzle which is single shot and a different design, the needle has a little rod on top which normally sits against the spring and the needle top itself is 0,3mm lower then the nozzle so the total needle movement is limited to that 0,3mm which is the same as with the LaRo injectors.

Since I want to copy the LaRo setup I have to remove the little bar on top of the needle and cut away 0.3mm of the top of the nozzle so needle and nozzle are lined up.

My first attempt was in the lathe but since all parts are machined at micron level (there are no gaskets between they are pressure tight steel on steel) that didn't work out very well I used a fine diamond cutting disc used to sharpen drills and machine tools.

I attached it in my mill running high speed with the nozzle on the table and only turning the X axis with a successful outcome.

Also the Scania nozzles are thicker then the originals, 9.07 v.s. 7.07mm so we need to cut them back in the lathe or we have to drill bigger holes in our cylinder head.

Drilling bigger holes is more convenient and safer (cutting back the nozzle can ruin them) but when making over 400BPH and temperatures over 1000 degree Celsius the head will start getting soft and the valve seats will drift away in the direction of the injector so when making the hole bigger that will happen a bit sooner.

What I do is only cutting back the first 10mm of the nozzle so I don't have to drill away material around my valve seats but even in this way there is a 50% chance the nozzle is ruined. (when cutting back the nozzle you go trough the hardened surface and internal tensions can bend it so the needle won't move so good or doesn't close anymore)

So to wrap it up, the easy way is making a single shot but that will have a pretty rough idle but doesn't require more then a grinder and the hard way is a 2-shot injector.

I always use a fine waterproof grinding paper on the inside of the nozzle and the needle itself so it gains a couple of microns more clearance and that will also remove factory oil and coating.

Lubricate before mounting with lots of WD40 and tighten the nozzles with 50Nm.

And make sure everything is very very very very clean before mounting!

![[Image: F6918064-01_zpsp6ekhzab.jpg]](http://i4.photobucket.com/albums/y113/petedut/F6918064-01_zpsp6ekhzab.jpg)

![[Image: 2ljm03k.jpg]](http://i57.tinypic.com/2ljm03k.jpg)