Posts: 43

Threads: 2

Joined: Nov 2016

Reputation:

0

Location: Leeds/York

Car Model/Spec: 182, 205, 330d

Thanks: 0

Given 0 thank(s) in 0 post(s)

It's a tough one with regards to the back axle ratio as normally larger axle from big vans and 7.5 tonners have a ratio of 4.5 upwards,

the other option is go to the scrappers and remove the whole rear subframe assembly from a 530d bmw, they have a ratio of around 2.5 and the post 2011 cars can handle 550 + ft.lb, the gearbox you have out of the leyland roadrunner will fail earlier than that.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

If you can mock up mounts with thin wood, let me know, i have a weldking on hand who can get them lasered up and then welded. Do a seriously good job for very little

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

(12-12-2016, 07:58 PM)darrenjlobb Wrote: If only I lived near london, would be all over this project if I did! Personally think it would be more win with a TH400 behind it and big 9" rear end, then you can really lay into the motor and have some serious fun, that and plate up the chassis somewhat from what it is at the moment! I know you'd be all over it if you were closer. I do intend to bring it down to you when it's done for some fettling and to make sure a diesel is back to the top of your power board.

The Th400 isn't my thing but rear axle upgrades are on the cards as I've been watching too many videos of Americans running land speed records in RWD bib block V8 cars. It would be cool to have something hat would run down in the 10s on a 1/4 mile and I'd probably need a 2:1 ratio to get the right top speed with a little head room.

(12-12-2016, 08:53 PM)Danny Wideboy Wrote: If you need another engine crane whenever, for whatever. Gimme a shout. It'll just sink too, I tried it with the weight split between my crane and my trolley and all 10 wheels were sinking.

(12-12-2016, 08:53 PM)BashRacing Wrote: It's a tough one with regards to the back axle ratio as normally larger axle from big vans and 7.5 tonners have a ratio of 4.5 upwards,

the other option is go to the scrappers and remove the whole rear subframe assembly from a 530d bmw, they have a ratio of around 2.5 and the post 2011 cars can handle 550 + ft.lb, the gearbox you have out of the leyland roadrunner will fail earlier than that. Yeah the 550lb/ft capability might not be enough, the engine makes 400lb/ft as standard and will quickly get up to 1000lb/ft. Also for now I can get 6 stud wheels with tyres cheap, sets for BMWs (or anything else RWD) aren't as cheap. The ZF gearbox takes plenty of power standard as lots of people are using them, obviously it's not perfect but it's a start. Still watching what I want on ebay, hoping I can low ball the bloke when I get my next lump of money from work probably mid January.

(12-12-2016, 09:08 PM)Piggy Wrote: If you can mock up mounts with thin wood, let me know, i have a weldking on hand who can get them lasered up and then welded. Do a seriously good job for very little  Thanks for the offer dude, but I really have decided that I'm just gonna buy a set. I might speak to you if I need something lasering up for the gearbox mount.

Posts: 440

Threads: 8

Joined: Jun 2013

Reputation:

1

Location: South Shroshire

Car Model/Spec: 405 SRDT

Thanks: 1

Given 6 thank(s) in 6 post(s)

[/quote]

Believe it or not I do know someone with a tractor, there is a bloke across the road (on my quiet and very residential street) who owns a mint restored tractor (don't know what it is) but sadly it doesn't have forks or anything on the front. I don't know anyone else local with anything suitable. Gutted as if I was still in London I know a couple of people who own horse riding stables and thus have suitable tractors.

I have considered making the engine mounts but to do that I'd need to have the engine in and out a dozen times plus the cost of the steel, plus not having a welder that can weld metal that thick (obviously I could tack it and then pay someone to weld) plus getting rubbers and my inability to accurately measure and then cut anything. It just makes sense for me to blow a few hundred quid on mounts that will fit and work and not fall apart or give up at an inconvenient moment and save me alot of work.

The gearbox mounts I can do myself as I can support the gearbox from above and then work on it from underneath using some 3mm wall box. Also I can't find a suitable ready made mount.

[quote]

If you use something as thick as Darrens suggesting you'd be best off mocking it up with something else instead of metal and tacking it imo. To weld 10/12mm without some proper prep needs a bloody poky 3 phase welder really cranked up. If you tacked them together someone would have to take them apart to prep them and then you'd pretty much be back to square one again if the project wasn't infront of you.

I used to weld 10 and 12mm engine beams for Sealine S48 cruisers regularly years ago. They come standard with a couple of 500 BHP Volvo Pentas on board so needed to be pretty beefy! The heat from the welder used to turn the gauntlet into a shrivelled claw over time and you had to run a water cooled torch too.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

Water cooled torch... Now we're talking

Posts: 440

Threads: 8

Joined: Jun 2013

Reputation:

1

Location: South Shroshire

Car Model/Spec: 405 SRDT

Thanks: 1

Given 6 thank(s) in 6 post(s)

(12-12-2016, 09:53 PM)Piggy Wrote: Water cooled torch... Now we're talking

Still wasn't enough to stop the ends of the tips suddenly evaporating from time to time tho.

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

All these comments spurred me on to actually do something with this today. Shock horror I've actually fitted something to it!!! more on that later.

I removed the red security thingamy on the max fuel screw, removed a bracket from the air compressor and then moved the bosch VE rear bracket, removed the hydraulic pump and FITTED THE 12V STOP SOLENOID!!!

I then attacked the LDA and got the security cover off that. Sadly the actual screws put up alot more of a fight than the security cover did and I can't budge them so gonna blast them with plus gas and leave them for a while.

I also removed most of the oil filler tube (need a 1 1/4" core plug to blank it properly) as it's gotta go so I can fit my engine mounts. I'm gonna buy a rocker cover with an oil filler in it. I also cleaned off some dirt to uncover the rear dipstick hole so I can use that when I flip the sump. I need to get an 18mm spanner as my 17mm is just too small to go over the air compressor bolts or the bolts on the drive shaft and 19mm is huge. I'm a little worried that they are actually gonna be 11/16ths but there's only one way to find out LOL.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

I often use a small pair of vicegrips aswell as screwdriver on a socket on those lda bolts... Swiftly replaced with m6 bolts lol

Posts: 391

Threads: 29

Joined: Sep 2014

Reputation:

0

Thanks: 1

Given 7 thank(s) in 7 post(s)

You going to degrease and jet wash the beast?

Posts: 3,539

Threads: 42

Joined: Mar 2012

Reputation:

28

Thanks: 3

Given 89 thank(s) in 88 post(s)

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

(14-12-2016, 12:07 AM)Piggy Wrote: I often use a small pair of vicegrips aswell as screwdriver on a socket on those lda bolts... Swiftly replaced with m6 bolts lol I was using a big adjustable on the square shaft of the driver and the screwdriver was just trying to climb out of the groove.

Going to try a screwdriver bit in a ratchet.

(14-12-2016, 07:38 AM)allye Wrote: You going to degrease and jet wash the beast? Already jet washed it on the day I picked it up. I might try cleaning it further but the grime is so caked on that the best way to remove it is scraping it off with a pry bar.

![[Image: attachment.php?thumbnail=28848]](http://306oc.co.uk/forum/attachment.php?thumbnail=28848)

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

Yeah the flat blade always does I've found...maybe the bosch gurus have a better way... But I've always used a fixed head 3/8 with a flat blade socket on it, then a set of small vicegrips on the head of the machine screw itself (not the socket or screwdriver) and apply force on both.

Ive seen people use little impact wrenches (smack with a hammer) but I'd be worried about breaking the housing

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

Yeah Piggy that's my worry too, don't want to strip the thread out the ally (assuming steel screws into ally have fused with dissimilar metal corrosion) or worse crack the whole top of the pump. Gonna give Plus Gas a chance and the ratchet. I like the idea of helping the head with the grips though.

Posts: 1,417

Threads: 34

Joined: Dec 2011

Reputation:

8

Thanks: 0

Given 8 thank(s) in 8 post(s)

Hammer and pin punch to crack them?

Sent from my LG-H850 using Tapatalk

Posts: 440

Threads: 8

Joined: Jun 2013

Reputation:

1

Location: South Shroshire

Car Model/Spec: 405 SRDT

Thanks: 1

Given 6 thank(s) in 6 post(s)

21-12-2016, 05:27 PM

(This post was last modified: 21-12-2016, 05:27 PM by Paul Baldwin.)

http://www.kenteurope.com/en/products/rusty-penetrant

I've used this stuff in the past to very good effect, especially if you have time to let it work. It seems to be trade only tho and I haven't been able to get hold of any lately.

Other than that, what others and said and as much impact as you dare to give them. I've never found plus-gas or WD-40 especially to be much use tbh.

Posts: 4,566

Threads: 102

Joined: Dec 2011

Reputation:

9

Location: Sunderland

Thanks: 60

Given 14 thank(s) in 14 post(s)

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

(29-12-2016, 02:10 PM)procta Wrote: I will leave this here for you

https://www.youtube.com/watch?v=KkxXXfz1tdA

I've seen loads of pics of that as I follow his build on Facebook. It's super clean.

Posts: 4,566

Threads: 102

Joined: Dec 2011

Reputation:

9

Location: Sunderland

Thanks: 60

Given 14 thank(s) in 14 post(s)

(30-12-2016, 09:22 AM)Dum-Dum Wrote: (29-12-2016, 02:10 PM)procta Wrote: I will leave this here for you

https://www.youtube.com/watch?v=KkxXXfz1tdA

I've seen loads of pics of that as I follow his build on Facebook. It's super clean.

i have read the thread on it on the forum, its going to be topper when its complete!

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

More bits have come in the post, now got an oil filler as the standard Daf45 location will be blocked by the engine mounts I plan to use. Also have the appropriate core plug to block the original oil filler.

Sorry for the boring update, it's too cold to be outside spannering on this.

Posts: 908

Threads: 70

Joined: May 2013

Reputation:

10

Location: Bedford

Car Model/Spec: HDi Estate

Thanks: 4

Given 9 thank(s) in 9 post(s)

So hard to get a sense of scale from that photo!

Could be like anything from 1 inch to 1 foot, great skills!

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

(03-01-2017, 12:15 PM)tigerstyle Wrote: So hard to get a sense of scale from that photo!

Could be like anything from 1 inch to 1 foot, great skills!

I suppose it is LOL. It's a rocker cover to replace one of my 6, the base is about A6 size by about 3" high.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

04-01-2017, 06:55 AM

(This post was last modified: 04-01-2017, 06:55 AM by Piggy.)

Ahhhh I thought it was the core plug

(a very weird looking one!)

Posts: 908

Threads: 70

Joined: May 2013

Reputation:

10

Location: Bedford

Car Model/Spec: HDi Estate

Thanks: 4

Given 9 thank(s) in 9 post(s)

I like the cryptic photography! Keep us guessing

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

(04-01-2017, 06:55 AM)Piggy Wrote: Ahhhh I thought it was the core plug

(a very weird looking one!) Photo of that being fitted soon, it's far too boring on it's own.

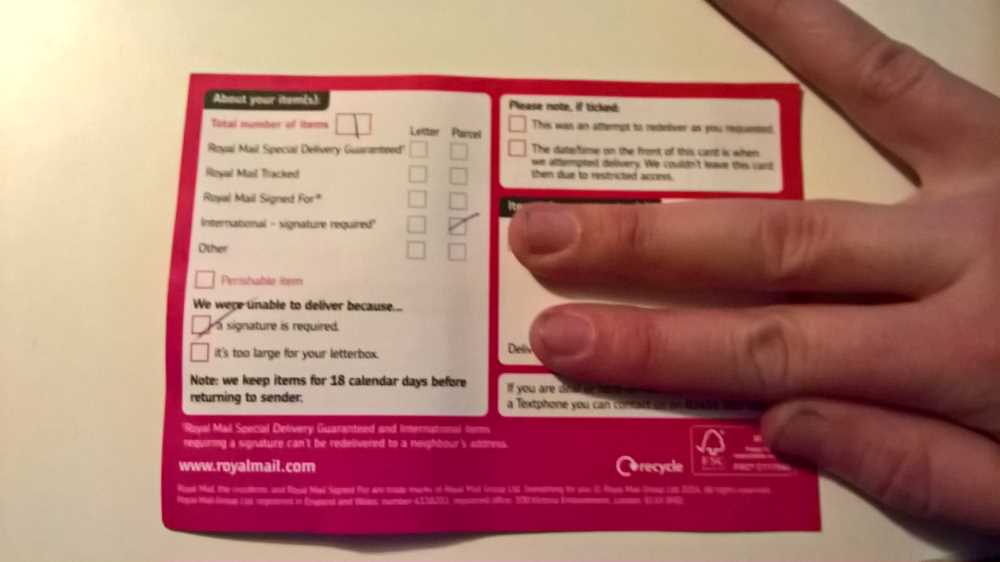

(04-01-2017, 09:05 AM)tigerstyle Wrote: I like the cryptic photography! Keep us guessing  Ooh well if you like the cryptic photography can you guess what this relates to?

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

Posts: 5,902

Threads: 142

Joined: Dec 2011

Reputation:

58

Location: Hastings, East Sussex

Car Model/Spec: E46 BMW 320d

Thanks: 17

Given 28 thank(s) in 28 post(s)

(04-01-2017, 12:36 AM)Dum-Dum Wrote: (03-01-2017, 12:15 PM)tigerstyle Wrote: So hard to get a sense of scale from that photo!

Could be like anything from 1 inch to 1 foot, great skills!

I suppose it is LOL. It's a rocker cover to replace one of my 6, the base is about A6 size by about 3" high.

This is why you should always use a banana for scale.

Posts: 3,419

Threads: 120

Joined: Jan 2014

Reputation:

35

Location: Powys / Herefordshire

Car Model/Spec: Rallye/S16 & 175 megane

Thanks: 147

Given 40 thank(s) in 40 post(s)

(04-01-2017, 09:46 PM)cully Wrote: New rubber truncheon?

I was thinking the same!

![[Image: 17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg]](http://i143.photobucket.com/albums/r143/matt-taylor/17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg)

Team Cyril

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

Any further guesses than a sex aid?

Posts: 908

Threads: 70

Joined: May 2013

Reputation:

10

Location: Bedford

Car Model/Spec: HDi Estate

Thanks: 4

Given 9 thank(s) in 9 post(s)

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

No!

|

![[Image: P1060836_zpsz3xgxt7q.jpg]](http://i1101.photobucket.com/albums/g427/wingnutz2/P1060836_zpsz3xgxt7q.jpg)

I was thinking the same!

I was thinking the same!

![[Image: 17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg]](http://i143.photobucket.com/albums/r143/matt-taylor/17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg)