MOT time! was very nervous about the whole thing! But thankfully it all passed! Finally, was missing the pug so much and it was time to get it back on the road!

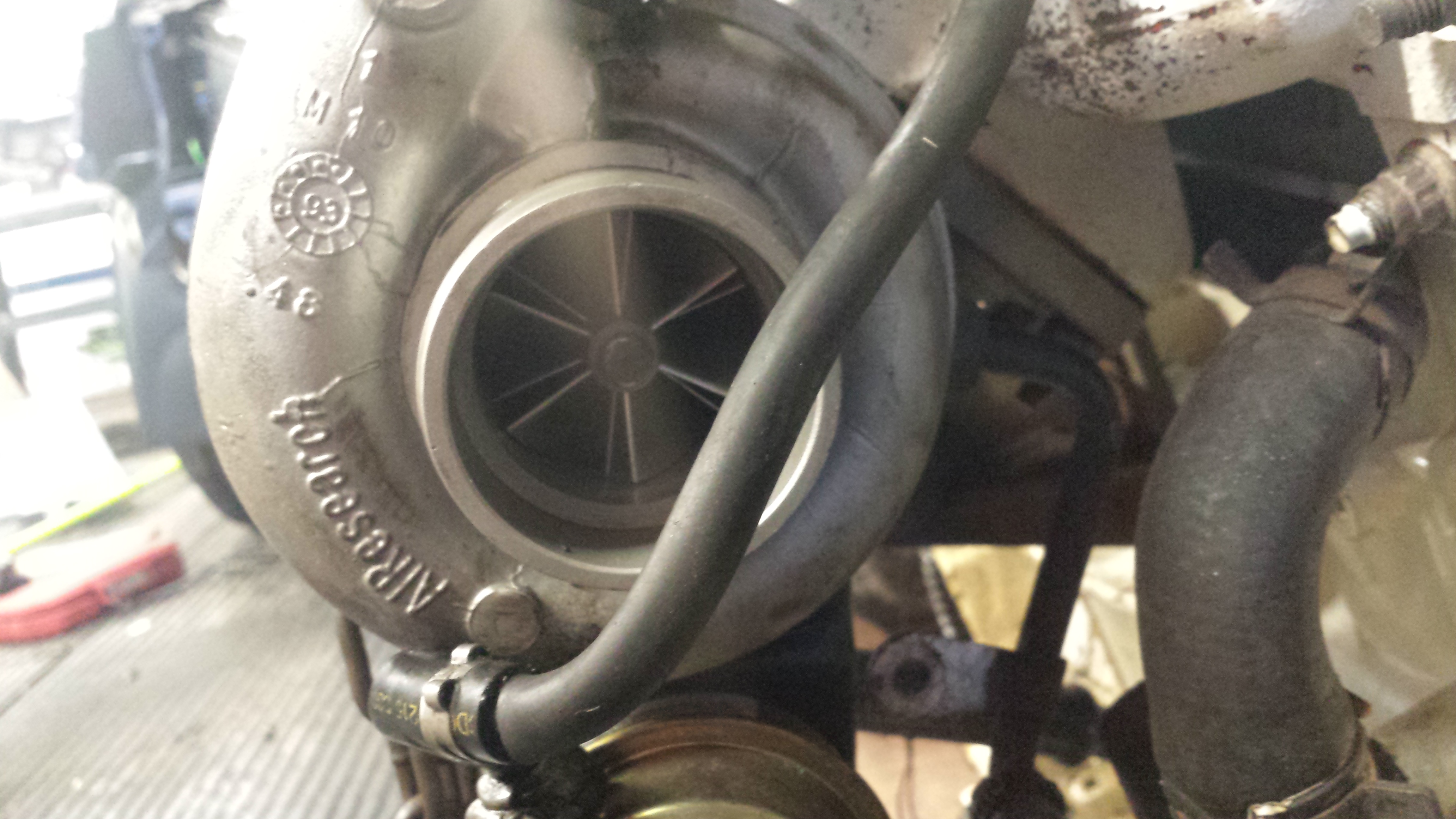

S**t....dont think it lasted more than two days! all efforts to try and nurse the turbo from it sitting so long had failed and it was smoking...a lot...! it was completely screwed and there not the easiest of engines/parts to come across. Managed to get hold of one that needed a recon and off to turbo dynamics it went for a makeover.

a shiny new hybrid turbo arrived. Much better performing than the stock one and worked brilliantly. Took a while to get all the oil burned off from down the exhaust and it also took out the lambda sensor through contamination. But it was back to being on the road again!...round 2!

after a little while of running around like this. It became apparent that the gearbox wasn't going to be enough. It would top out very quickly meaning i was sitting on motorways at lorry pace otherwise it would scream its nuts off. It would accelerate very quickly and you couldn't change gear quick enough! but it just wasn't quite what i was looking for. This also gave me the opportunity to tidy up some of the wiring as everything was now tested on the road and i also planned to move the battery to the boot to get more space.

So out it came again! nice and easy this time as most of the hard work is done

fresh coat of paint to clean things up a bit. At this point i had the banded steels the same cream colour so i thought i would tie that in to the bay! unfortuanley they are very messy engines and although you can get rid of a lot of things or make it look smarter, its all on a small budget and the expense just didnt justify the results for the amount of work. It looks good up until you start bolting things on it!

All back together again. Another thing worth mentioning is that i also had to move the washer bottle to the boot to make room for the intercooler piping. Takes a while to get screenwash up to the front but it works a treat. With the new turbo diesel gearbox on it behaved so much better on the road. i could actually go down the motorway and the gears where a lot longer which made better use for the turbo.

The car stayed like this with a few more refinements for a little while. After a trip round the track at bhp, it was obvious i needed something more than the 165 tyres i had on the banded steels...and brakes became a problem after about the 4th corner -.- But i couldnt believe it made it round there and was a brilliant moment when the flag came out thinking that something i had slapped together managed to even make it a lap let alone the session and with the gf in the car next to me i had a massive massive smile on my face.

Since then its was waiting on its custom made extreme offset wheels to be delivered which look phresh! And recently just put on the wind deflectors as well as the rear spoiler to tie it together.

![[Image: 20120704_212316.jpg]](http://i789.photobucket.com/albums/yy175/DanHargrave/20120704_212316.jpg)

i mean its his garage n all but pug priorities

i mean its his garage n all but pug priorities

![[Image: signature.png]](http://s22.postimg.org/cgh3ss11t/signature.png)