Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

Special tools bought so far for disassembly

Head bolt tool

T55 Torx Key Bit Socket Approx 78mm overall length and 1/2 square drive

note!

OK for disassembly but will need a longer one to reassemble if you want to assemble the cams in the head off of the block,

as it wont fit between the cam carriers once the cams are installed.

Valve spring compressor

Needs to be able to compress the springs within the recesses of the head and leave room to remove the valve Colet's

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

Top tip!!

keep all your bolts in sets and seperate them from each other

ie:

inlet mani bolts

exhust mani bolts

rocker cover bolts

cam carrier bolts

cambelt cover bolts

ect ect

it makes it easyer to sort out which bolt go's where

i have used bank bags for this, there free go and ask for some at the bank

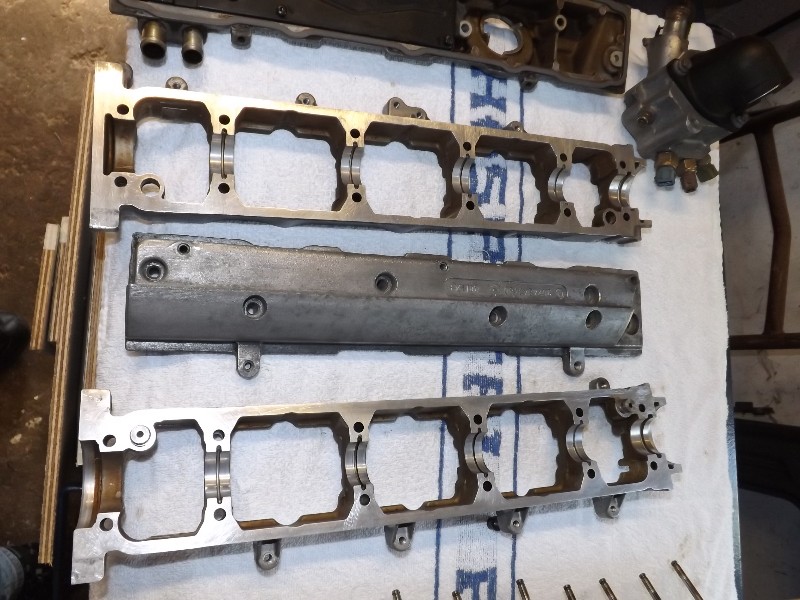

have spent a couple of hours cleaning off the cam carriers and covers, there are no gaskets used here only assembly snot that sticks it all together looks like araldite when its gone off

i used a stanley craft knife blade,wire wool,and a wire brush

Dont remove the grey rubbery gasket on the cam covers as this is reusable just clean it up,

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

Nice work mate. Looking really clean.

Posts: 7,152

Threads: 130

Joined: Jan 2012

Reputation:

82

Location: Kingston

Car Model/Spec: 106 GO-NAD

Thanks: 0

Given 0 thank(s) in 0 post(s)

My my, so organised. You're a fart smeller Paul

Member of the 99% warning or you're nothing club

Posts: 19,854

Threads: 581

Joined: Dec 2011

Reputation:

195

Location: Bournemouth

Car Model/Spec: Supercharged 306 GTi6

Thanks: 36

Given 82 thank(s) in 78 post(s)

If i was you Cully, replace them cam pulleys with the later single bolt versions. Them ones have a known issue where they let go! Would be shit to do all this hard work for you to mash the top end up if they break!

Team Eaton

1999 China Blue 306 GTi6 - Eaton Supercharged - 214.5bhp 181lbft

Posts: 408

Threads: 40

Joined: Mar 2013

Reputation:

0

Location: Devon

Car Model/Spec: Moonstone Ph3 GTi-6

Thanks: 0

Given 0 thank(s) in 0 post(s)

(06-10-2013, 06:09 PM)Niall Wrote: If i was you Cully, replace them cam pulleys with the later single bolt versions. Them ones have a known issue where they let go! Would be shit to do all this hard work for you to mash the top end up if they break!

Like what just happened to mine? :'(

Posts: 19,854

Threads: 581

Joined: Dec 2011

Reputation:

195

Location: Bournemouth

Car Model/Spec: Supercharged 306 GTi6

Thanks: 36

Given 82 thank(s) in 78 post(s)

(06-10-2013, 06:11 PM)callumcull Wrote: (06-10-2013, 06:09 PM)Niall Wrote: If i was you Cully, replace them cam pulleys with the later single bolt versions. Them ones have a known issue where they let go! Would be shit to do all this hard work for you to mash the top end up if they break!

Like what just happened to mine? :'(

Shit  . They didnt do too well when designing the 6 engine for non belt breaking. lol

Team Eaton

1999 China Blue 306 GTi6 - Eaton Supercharged - 214.5bhp 181lbft

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

ok if i were to change to the later single bolt pulleys would i have to change to the later cambelt with the auto tensioner

as my set up has the stronger manual tensioner i bellieve the later belts have an extra tooth??

Posts: 408

Threads: 40

Joined: Mar 2013

Reputation:

0

Location: Devon

Car Model/Spec: Moonstone Ph3 GTi-6

Thanks: 0

Given 0 thank(s) in 0 post(s)

Any idea where I'd be able to pick up those cam pulleys so I can fit them when/if I find a sound engine to buy and fit in my 6? :/

Posts: 19,854

Threads: 581

Joined: Dec 2011

Reputation:

195

Location: Bournemouth

Car Model/Spec: Supercharged 306 GTi6

Thanks: 36

Given 82 thank(s) in 78 post(s)

(06-10-2013, 06:16 PM)cully Wrote: ok if i were to change to the later single bolt pulleys would i have to change to the later cambelt with the auto tensioner

as my set up has the stronger manual tensioner i bellieve the later belts have an extra tooth??

Nope they are exactly the same diameter. You can use either type of tensioner but you have to match it to the right belt. I think the auto plastic type is the 137 tooth belt and the manual metal one is 136.

(06-10-2013, 06:16 PM)callumcull Wrote: Any idea where I'd be able to pick up those cam pulleys so I can fit them when/if I find a sound engine to buy and fit in my 6? :/

Any late ph2 or ph3 gti engine mate

Team Eaton

1999 China Blue 306 GTi6 - Eaton Supercharged - 214.5bhp 181lbft

Posts: 408

Threads: 40

Joined: Mar 2013

Reputation:

0

Location: Devon

Car Model/Spec: Moonstone Ph3 GTi-6

Thanks: 0

Given 0 thank(s) in 0 post(s)

Posts: 19,854

Threads: 581

Joined: Dec 2011

Reputation:

195

Location: Bournemouth

Car Model/Spec: Supercharged 306 GTi6

Thanks: 36

Given 82 thank(s) in 78 post(s)

(06-10-2013, 06:23 PM)callumcull Wrote: But, my 6 is ph2...

Late ph2s. So ph2.5 really lol. Find someone breaking a PH3 and it will definitely have them on.

Team Eaton

1999 China Blue 306 GTi6 - Eaton Supercharged - 214.5bhp 181lbft

Posts: 3,377

Threads: 96

Joined: Dec 2011

Reputation:

7

Location: Brizzel

Car Model/Spec: 306 tractor

Thanks: 0

Given 0 thank(s) in 0 post(s)

SHIT gotta give this new engine the best chance of staying alive

Didn't know they a bad problem !

![[Image: siggy1.jpg]](http://i653.photobucket.com/albums/uu252/crissy_boy/Cars/siggy1.jpg) the smokey old bus that sounds like a tractor...

the smokey old bus that sounds like a tractor...

Posts: 8,298

Threads: 289

Joined: Nov 2011

Reputation:

92

Location: London

Car Model/Spec: Phase 17 R26

Thanks: 0

Given 1 thank(s) in 1 post(s)

Awesome progress buddy

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

been on the phone today trying to find info about head heights std and max skim depths

the engine machine shop that my mate uses didn't know the tech on the XU10J4RS head so had to think who to phone,

i chanced my luck and phoned Peugeot Exeter and i got through to a helpful chap who did the trawling and phoned me back

according to Peugeot Exeter

the 16valve rs head should be stamped on the casting with an ® on the inlet side near the cam sensor on a machined plate.

the maximum you can skim the head is 0.2mm

the head new hight between finished faces Top>Bottom between cam seal end is

137mm New so the maximum you can skim too is 136.8mm

and guess what my head is................yup 136.8mm

so now Ive got to find out if the head is true/flat so tomorrow in my dinner hour

if found that we have an engineers plate in work and some engineers blue so i should be able to do this myself

but the engine place my mate uses did say he would check it for free

his prices for work are

skim £25+vat

3 seat cut valve grind is £5.50+Vat per valve

so tomorrow will tel me if i have a flathead

other info i found

8 valve head stamped R2, new hight 137mm, max skim 0.4mm.

Posts: 6,569

Threads: 183

Joined: Dec 2011

Reputation:

20

Location: eastwood/notts

Car Model/Spec: moonstone hdi #2

Thanks: 0

Given 8 thank(s) in 8 post(s)

Getting some great information here cully. Keeping a very close eye on this.

#2 Moonstone Blue HDI

![[Image: 6b0c7309-5184-463c-9f73-2a7b96601418_zpsfdf041fe.jpg]](http://i512.photobucket.com/albums/t326/kent16_2008/6b0c7309-5184-463c-9f73-2a7b96601418_zpsfdf041fe.jpg)

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

the head is saved!

ok

to check the head for true

sheet of glass on a flat surface, coat the glass in engineers blue which is a dyed grease,

now rub the head in a figure of eight motion on the glass and blue,

role head over and the high spots will pick up the blue on the head the unmarked areas are low points,

my head was almost all covered,

so i decided to "lap" the head instead of haveing it skimmed as the head was at its maximum cut

to lap the head is the same principle as the engineers blue method but with fine grinding paste,

coat glass with fine grinding/lapping compound

place head on glass and rub in the figure 8 motion

perodicly check buy turning head over you are now looking for a unifom grey finish

this then means you have taken enough meterial off to flaten the high spots

you can recheck this with the engineers blue but you can see the finish easy when you clean the face with WD40 it looks clean and grey

remember you need to clean the head well as you have used gringing compound

you dont want this in the engine

so now i have 16 Valves to clean and to lap in should take me a while

Posts: 19,854

Threads: 581

Joined: Dec 2011

Reputation:

195

Location: Bournemouth

Car Model/Spec: Supercharged 306 GTi6

Thanks: 36

Given 82 thank(s) in 78 post(s)

I swore after lapping the valves on my 1.8 head i wouldnt touch another. Shame i couldnt stick to that! lol

Team Eaton

1999 China Blue 306 GTi6 - Eaton Supercharged - 214.5bhp 181lbft

Posts: 648

Threads: 46

Joined: Jul 2013

Reputation:

6

Location: Bridlington

Car Model/Spec: Renault Scenic 2.0

Thanks: 0

Given 6 thank(s) in 6 post(s)

Awesome  i love how clean the surfaces can look when they're properly sorted like this, hope the rest is as good

Project: Formula Peugeot

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

ok finished head hight still at tollerance

and finished head face

Posts: 3,377

Threads: 96

Joined: Dec 2011

Reputation:

7

Location: Brizzel

Car Model/Spec: 306 tractor

Thanks: 0

Given 0 thank(s) in 0 post(s)

Fantastic work Paul, this engine will be very smooth and efficient if the rest of the build is this meticulous

Fancy doing a Bosch conversion on mine

![[Image: siggy1.jpg]](http://i653.photobucket.com/albums/uu252/crissy_boy/Cars/siggy1.jpg) the smokey old bus that sounds like a tractor...

the smokey old bus that sounds like a tractor...

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

11-10-2013, 11:54 AM

(This post was last modified: 11-10-2013, 11:55 AM by cully.)

New Tool time!

i bought a 150mm wire brush for my bench grinder just for cleaning up the valves (£7 tool station)

it made light work of cleaning up the exhaust valves of the carbon deposits

on the stem side i only cleaned up to the valve guide so to minimise damage to the stem

valves are ready to be ground in once the heads pressure tested

Warning though!

always use goggles with these and any grinding wheels

your eyes are important to you

Posts: 5,847

Threads: 169

Joined: Dec 2011

Reputation:

91

Location: South London

Car Model/Spec: 2003 Jaguar S-Type Sport 3.0V6

Thanks: 1

Given 1 thank(s) in 1 post(s)

Great little tip on the glass and fine grinding paste there cully!

Great progress!

![[Image: car-1.jpg]](http://i1117.photobucket.com/albums/k591/grant-306/car-1.jpg)

Member of the 99% warning or you're nothing club

2000 Moonstone 1.8 Meridian - Sold

2000 China 3dr XS - Dead

1998 Diablo 3dr XSI

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

12-10-2013, 02:56 PM

(This post was last modified: 12-10-2013, 03:27 PM by cully.)

might of got a little carried away with the alloy primer

Valve grinding quick how to!

1. Take the correct valve for the valve port you have stored,

NOTE: the valve seat and the head seat how the mating surfaces are rough and discoloured this is poor seating

2. add small amount of fine valve grinding compound to valve seat area only

NOTE: dont get this on the valve stem as it will mess up the guides

3. slide valve carefully into valve guide using hand tool, using palms of both hands rub the stick as if your trying to light a fire

3. after a short period remove valve clean surfaces to check for seating

NOTE: you are looking for the grey colour ring, all around the valve seat and the head seat

things to watch for

bent valve!

if you have a bent valve the head seat will cut to the gray ring, but the valve will only show part the grey ring !

you have a scrap valve, no matter how much grinding you do you probably wont recover the valve before you grind the seat too deap

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

oscolating drill for the win when doing valve seats!!!

Posts: 3,377

Threads: 96

Joined: Dec 2011

Reputation:

7

Location: Brizzel

Car Model/Spec: 306 tractor

Thanks: 0

Given 0 thank(s) in 0 post(s)

(12-10-2013, 03:30 PM)Piggy Wrote: oscolating drill for the win when doing valve seats!!!

+1 but go slowly and be careful

![[Image: siggy1.jpg]](http://i653.photobucket.com/albums/uu252/crissy_boy/Cars/siggy1.jpg) the smokey old bus that sounds like a tractor...

the smokey old bus that sounds like a tractor...

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

12-10-2013, 07:32 PM

(This post was last modified: 12-10-2013, 07:33 PM by cully.)

(12-10-2013, 03:58 PM)devils_fuel Wrote: (12-10-2013, 03:30 PM)Piggy Wrote: oscolating drill for the win when doing valve seats!!!

+1 but go slowly and be careful

not going to be spending £30 on a valve lapper

when that could pay for head bolts and a waterpump

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

I normally use coarse then fine.

but gets long winded and hurts ya hands with a 16v!!!

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

more paint

|

. They didnt do too well when designing the 6 engine for non belt breaking. lol

. They didnt do too well when designing the 6 engine for non belt breaking. lol

![[Image: siggy1.jpg]](http://i653.photobucket.com/albums/uu252/crissy_boy/Cars/siggy1.jpg)

![[Image: 6b0c7309-5184-463c-9f73-2a7b96601418_zpsfdf041fe.jpg]](http://i512.photobucket.com/albums/t326/kent16_2008/6b0c7309-5184-463c-9f73-2a7b96601418_zpsfdf041fe.jpg)

![[Image: car-1.jpg]](http://i1117.photobucket.com/albums/k591/grant-306/car-1.jpg)