08-02-2018, 08:44 PM

It was pretty well covered by 'rikky' in this previous thread a few years back ... a reminder that we all stand on the shoulders of others. https://www.306oc.co.uk/forum/archive/in...26295.html

I've taken some pics tho and will try to clarify a few things. This is the order that all of the parts of the handbrake mechanism fit together .....

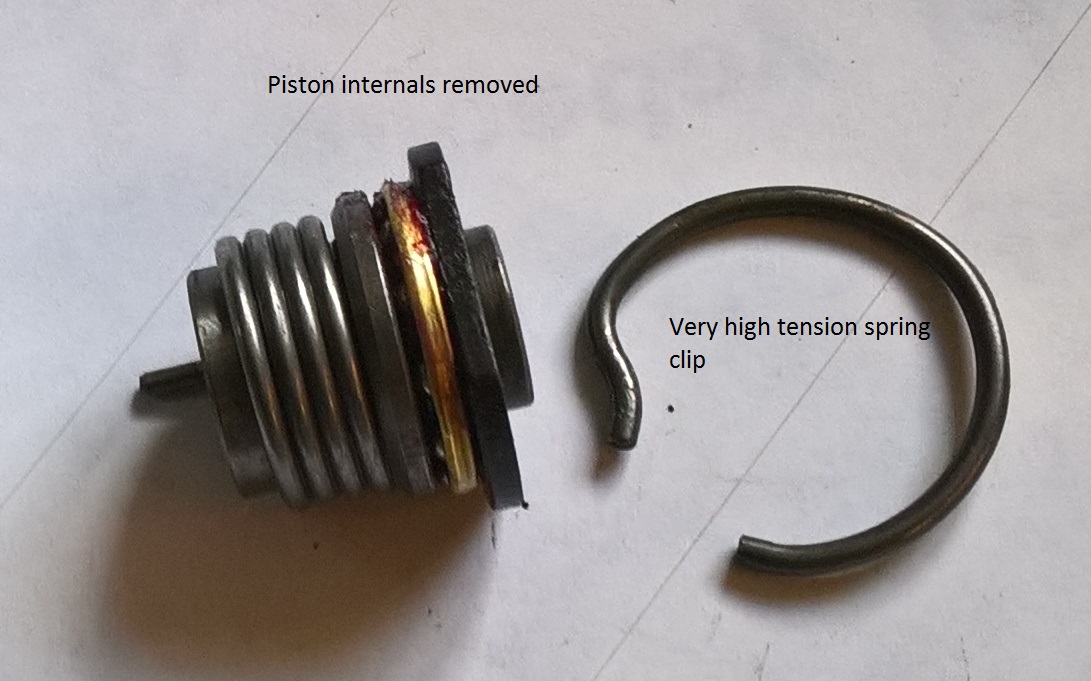

If you get new pistons they won't have any internals, which attach the piston to the rest of the handbrake mechanism. I don't yet have any advice on the best way to get the spring back to hold the piston internals in place.

Before assembly, fit new o-ring seals from kit.

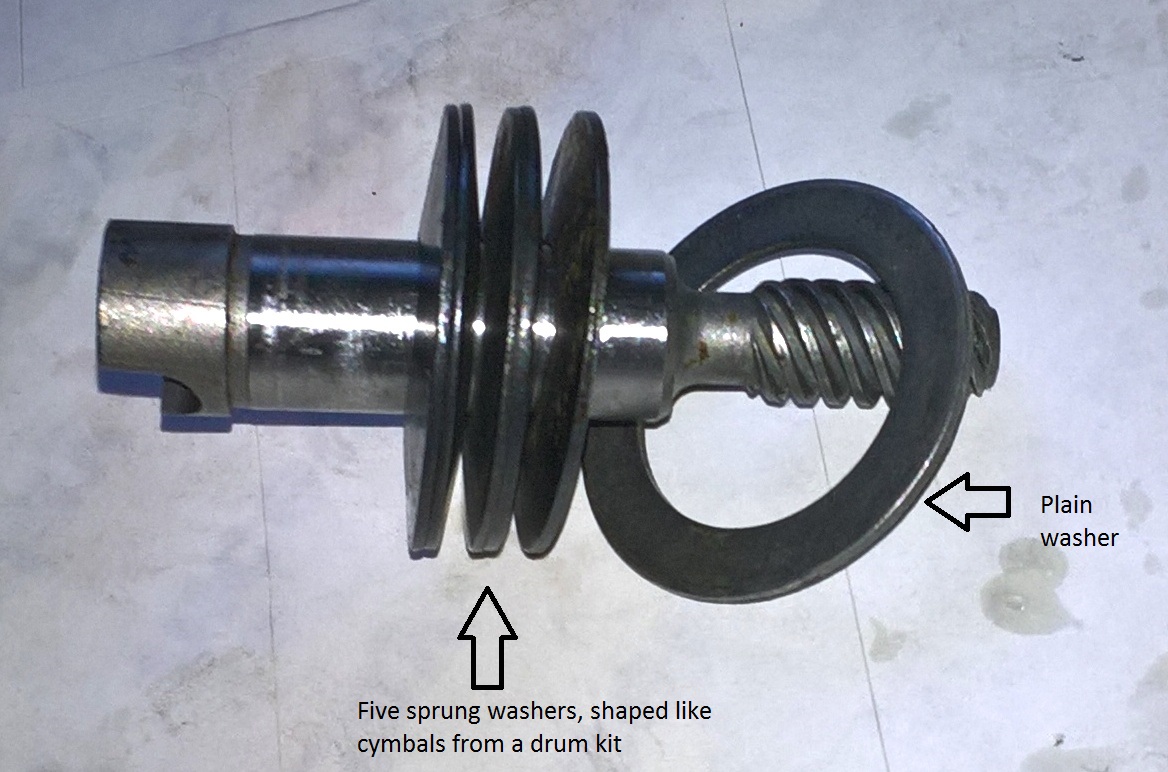

When putting the shaft with the threaded end back in to the caliper body, make sure the side that doesn't stick up so far faces towards the sliders. The fatter side of the key sits on the end of the shaft. The lever arm has a groove/slot machined in to it that mates with the top of the key.

A closer look at the sprung washers that will need to be compressed to get the lever arm back through and on to its bushes. IMPORTANT - You need to insert the lever arm in to the rubber boot and turn the boot inside out before sliding it through the bushes. (The boot can't be put on after the mechanism has been put together).

The tool you will have made to compress the washers will obscure your view of the key when you insert the lever arm. That's the really tricky bit. Make sure the key is centred before releasing compression on the sprung washers.

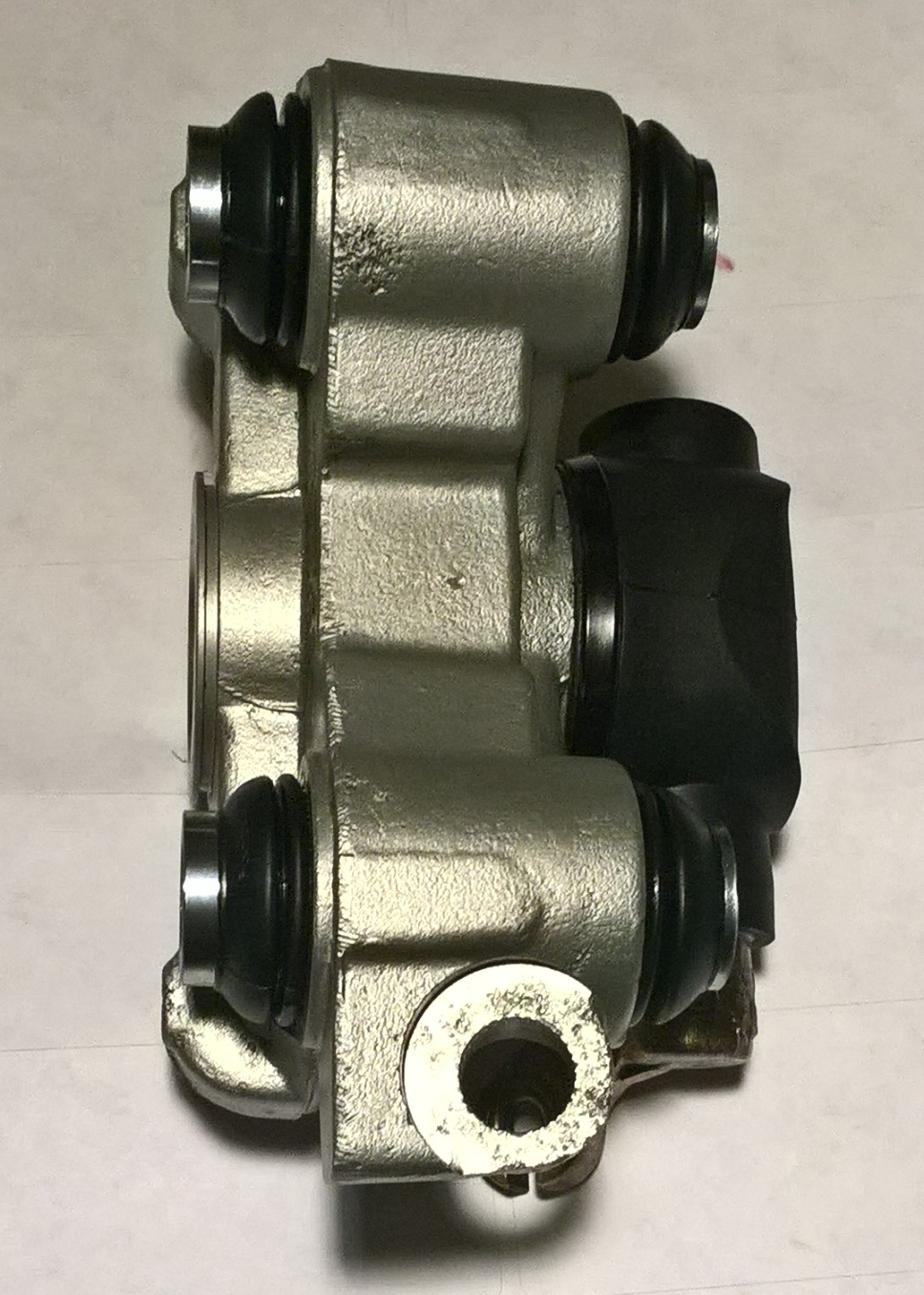

When putting the sliders back in pay attention to orientate them correctly (the ends aren't symmetrical)

Pack the handbrake mechanism with grease (I used lithium grease) before pulling the protective rubber boot over and securing with a zip tie.

I've taken some pics tho and will try to clarify a few things. This is the order that all of the parts of the handbrake mechanism fit together .....

If you get new pistons they won't have any internals, which attach the piston to the rest of the handbrake mechanism. I don't yet have any advice on the best way to get the spring back to hold the piston internals in place.

Before assembly, fit new o-ring seals from kit.

When putting the shaft with the threaded end back in to the caliper body, make sure the side that doesn't stick up so far faces towards the sliders. The fatter side of the key sits on the end of the shaft. The lever arm has a groove/slot machined in to it that mates with the top of the key.

A closer look at the sprung washers that will need to be compressed to get the lever arm back through and on to its bushes. IMPORTANT - You need to insert the lever arm in to the rubber boot and turn the boot inside out before sliding it through the bushes. (The boot can't be put on after the mechanism has been put together).

The tool you will have made to compress the washers will obscure your view of the key when you insert the lever arm. That's the really tricky bit. Make sure the key is centred before releasing compression on the sprung washers.

When putting the sliders back in pay attention to orientate them correctly (the ends aren't symmetrical)

Pack the handbrake mechanism with grease (I used lithium grease) before pulling the protective rubber boot over and securing with a zip tie.