Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

Mate seeing DeeTurbos thread with similar symptoms to yours it turns out its his rail pressure sensor wiring at fault and as ive had to mess with the wiring on yours for the 1800bar sensor id say it would be worth a check.

Posts: 10,864

Threads: 117

Joined: Dec 2011

Reputation:

119

Location: Southampton

Car Model/Spec: 306 HDi and friends

Thanks: 13

Given 106 thank(s) in 106 post(s)

Was it soldered in properly, or was it a twist 'em together and that'll do job?

Posts: 4,883

Threads: 198

Joined: Jan 2012

Reputation:

135

Location: Not near you

Thanks: 0

Given 0 thank(s) in 0 post(s)

Dumdum wouldn't have even twisted them together trololol

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

I have a funny feeling they were bullet connectors so it would be easy to swap them back over if you wanted to run a standard rail sensor.

Posts: 4,604

Threads: 90

Joined: Dec 2011

Reputation:

54

Location: Cornwall

Car Model/Spec: 1996 306 DT M-TDI/16

Thanks: 0

Given 20 thank(s) in 18 post(s)

Jonny, Have you acually plugged pp2000 into this to see if there are any faults etc? And that rail pressure is normal, just to be sure its nothing silly?

| Dyno Power Runs & Steady State Facilities Available, Just Ask Anytime |

| #DervMafia |

![[Image: sigi-2.png]](http://i281.photobucket.com/albums/kk226/darrenjlobb/sigi-2.png)

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

10-02-2013, 10:11 AM

(This post was last modified: 10-02-2013, 10:12 AM by Jonny81191.)

I haven't, all I'm able to do is to check for codes. What I'm going to do is swap the lifters and rockers from my spare head and go from there. If that doesn't work then I'll have to get PP, which is on my list of things to get anyway.

Obviously this after I check the wiring..

Welding and fabrication projects undertaken, contact me for more information.

Posts: 1,897

Threads: 162

Joined: May 2012

Reputation:

21

Location: Dunstable

Car Model/Spec: 306 HDI Dturbo, Estate & GTI6

Thanks: 0

Given 23 thank(s) in 23 post(s)

10-02-2013, 10:30 AM

(This post was last modified: 10-02-2013, 10:32 AM by DeeTurbo.)

(09-02-2013, 10:52 PM)Dum-Dum Wrote: Mate seeing DeeTurbos thread with similar symptoms to yours it turns out its his rail pressure sensor wiring at fault and as ive had to mess with the wiring on yours for the 1800bar sensor id say it would be worth a check.

(10-02-2013, 09:21 AM)Dum-Dum Wrote: I have a funny feeling they were bullet connectors so it would be easy to swap them back over if you wanted to run a standard rail sensor.

I take it that the bullet connector were crimped on, if so did you have a good tug on them to see if wires were crimped nice and secure?

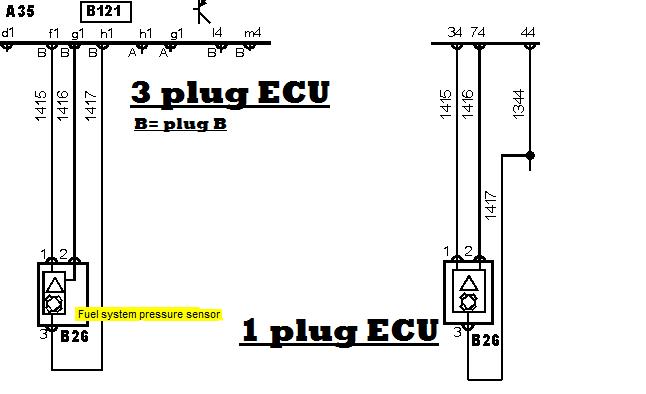

It might be worth doing a continuity check on the three cables from the plug on the sensor to the ecu.

--------FPS---------ECU

Pin------1-----------34

Pin------2-----------74

Pin------3-----------44 or pin 3 on the TPS

Posts: 4,604

Threads: 90

Joined: Dec 2011

Reputation:

54

Location: Cornwall

Car Model/Spec: 1996 306 DT M-TDI/16

Thanks: 0

Given 20 thank(s) in 18 post(s)

Swapping all the lifters / rockers is quite a palava, i wouldnt until ur sure thats the problem....

| Dyno Power Runs & Steady State Facilities Available, Just Ask Anytime |

| #DervMafia |

![[Image: sigi-2.png]](http://i281.photobucket.com/albums/kk226/darrenjlobb/sigi-2.png)

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

(10-02-2013, 10:30 AM)DeeTurbo Wrote: It might be worth doing a continuity check on the three cables from the plug on the sensor to the ecu.

--------FPS---------ECU

Pin------1-----------34

Pin------2-----------74

Pin------3-----------44 or pin 3 on the TPS

double check this as the car runs a three plug ECU

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

pin outs for both FPS

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

Well it was either the rockers or the lifters.

Swapped them for a set from a scrapyard engine, and it starts, runs and does 3.5krpm. I'll put it all back together properly tomorrow evening and check it makes power, but here's hoping that's fixed it for the time being

Welding and fabrication projects undertaken, contact me for more information.

Posts: 4,604

Threads: 90

Joined: Dec 2011

Reputation:

54

Location: Cornwall

Car Model/Spec: 1996 306 DT M-TDI/16

Thanks: 0

Given 20 thank(s) in 18 post(s)

Heh, well dont just go out and rag it again, ull just kill em again, hyrdro sucks, hence why I was going to solidize mine!

That said mine was still working fine at 6200rpm @ around 200hp

| Dyno Power Runs & Steady State Facilities Available, Just Ask Anytime |

| #DervMafia |

![[Image: sigi-2.png]](http://i281.photobucket.com/albums/kk226/darrenjlobb/sigi-2.png)

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

Don't worry  Lesson learned. Though I reckon it must have been Scott that killed it, he thought he was in a '6 when he had a little play

And stripping back another engine to components this weekend, coupled with the fact that I now have a spare block and head in my garage, has inspired me to build up a super strong HDi. And If I do, I'll definitely have solid lifters

Welding and fabrication projects undertaken, contact me for more information.

Posts: 896

Threads: 42

Joined: Apr 2012

Reputation:

2

Location: Lakes District

Car Model/Spec: 1.9 XUD

Thanks: 0

Given 0 thank(s) in 0 post(s)

What a relief

Posts: 7,825

Threads: 465

Joined: Dec 2011

Reputation:

114

Location: Cullompton Devon

Car Model/Spec: Vauxhall

Thanks: 1

Given 98 thank(s) in 92 post(s)

so did you find anything broken damaged?

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

Not really, all the lifters seemed to be the same, only thing was one of the rollers on a rocker felt rough, I'm guessing that could have been it. I'll check the lifters over when I get round to it.

Welding and fabrication projects undertaken, contact me for more information.

Posts: 8,298

Threads: 289

Joined: Nov 2011

Reputation:

92

Location: London

Car Model/Spec: Phase 17 R26

Thanks: 0

Given 1 thank(s) in 1 post(s)

(10-02-2013, 09:22 PM)Jonny81191 Wrote: Though I reckon it must have been Scott that killed it, he thought he was in a '6 when he had a little play Cheeky git  Never mind the 200 miles you did after I drove it

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

Welding and fabrication projects undertaken, contact me for more information.

Posts: 14,208

Threads: 448

Joined: Dec 2011

Reputation:

51

Location: isle of wight

Car Model/Spec: Pov. Spec White '6

Thanks: 17

Given 18 thank(s) in 18 post(s)

It's always the gingers fault

![[Image: 20A1806D-891D-40FB-BD52-AD519177A607-734...391753.jpg]](http://i35.photobucket.com/albums/d196/mattbush/20A1806D-891D-40FB-BD52-AD519177A607-7340-0000058F46391753.jpg) TEAM CONROD SHITTING RALLYE!

TEAM CONROD SHITTING RALLYE!

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

F*ck. F*ckity F*ck.

Lasted about a minute, seemed fine. Went to gently accelerate out of the 30 limit, not boosting, maybe 1/3rd throttle. Cut out, same symptoms. Started it up no problem, turned round and drove very slowly back. Felt like it was running on 3 cylinders and as I reversed down the drive there was a strong smell of unburnt diesel.

Not best pleased. Ah well. Life's a bitch, right?

Welding and fabrication projects undertaken, contact me for more information.

Posts: 8,298

Threads: 289

Joined: Nov 2011

Reputation:

92

Location: London

Car Model/Spec: Phase 17 R26

Thanks: 0

Given 1 thank(s) in 1 post(s)

Ah shit  That sucks dude

Posts: 18,242

Threads: 386

Joined: Dec 2011

Reputation:

87

Location: Suffolk

Car Model/Spec: Focus Titanium

Thanks: 1

Given 118 thank(s) in 117 post(s)

What was it you changed? The head?

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

11-02-2013, 10:53 PM

(This post was last modified: 11-02-2013, 10:53 PM by Jonny81191.)

It does, I'm beyond caring right now. I'll fix it though, and it WILL be epic. The bit that pisses me off the most is I really want to be working on the track car, as it's getting neglected ATM.

(11-02-2013, 10:52 PM)Toms306 Wrote: What was it you changed? The head?

Nah just the lifters and rockers.

Welding and fabrication projects undertaken, contact me for more information.

Posts: 18,242

Threads: 386

Joined: Dec 2011

Reputation:

87

Location: Suffolk

Car Model/Spec: Focus Titanium

Thanks: 1

Given 118 thank(s) in 117 post(s)

Oh right, is w shame it hasn't fixed it, just be frustrating! So, what's next then?

Posts: 1,897

Threads: 162

Joined: May 2012

Reputation:

21

Location: Dunstable

Car Model/Spec: 306 HDI Dturbo, Estate & GTI6

Thanks: 0

Given 23 thank(s) in 23 post(s)

Jonny, Did you check the fuel pressure sensor wiring when you were working on the lifters?

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

11-02-2013, 10:59 PM

(This post was last modified: 11-02-2013, 11:01 PM by Jonny81191.)

(11-02-2013, 10:55 PM)DeeTurbo Wrote: Jonny, Did you check the fuel pressure sensor wiring when you were working on the lifters?

Yeah, but first port of call is to solder them up solid now, I'll kick myself if that fixes it.

On a positive note, I've come up with a pretty awesome way of stiffening up engine mounts which works really well (or seemed to for the few seconds I got to drive it for)

I'll get some pictures tomorrow if I remember.

Welding and fabrication projects undertaken, contact me for more information.

Posts: 1,897

Threads: 162

Joined: May 2012

Reputation:

21

Location: Dunstable

Car Model/Spec: 306 HDI Dturbo, Estate & GTI6

Thanks: 0

Given 23 thank(s) in 23 post(s)

I found on my issue that it misfiring only at the beginning as I think the wire was catching on the block and earthing out. After I had a quick look about the engine bay while waiting for the RAC I think I might of moved the shorting wire away from the block and then after starting the car it was just in Limp mode. Mine was knackered near the second connector (yellow one).

Posts: 896

Threads: 42

Joined: Apr 2012

Reputation:

2

Location: Lakes District

Car Model/Spec: 1.9 XUD

Thanks: 0

Given 0 thank(s) in 0 post(s)

NOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

Time to change the name of your thread then...

Posts: 5,494

Threads: 202

Joined: Dec 2011

Reputation:

58

Location: Eastleigh

Car Model/Spec: S16 and HDi daily

Thanks: 2

Given 29 thank(s) in 28 post(s)

12-02-2013, 09:38 PM

(This post was last modified: 12-02-2013, 10:00 PM by Jonny81191.)

Yeah, so it's still broken after I fixed DumDum's pikey as fook wiring

I'm starting to think that I've broken a valve spring and it's causing valve bounce/float at comparatively low (2200 or so) RPM's, I just cannot believe that it's a valve sticking, considering it's idling OK.

Either way, I'm just gonna rebuild and fit my spare head. Then I know it's all good, I'll drop it into the engine shop tomorrow evening to get it skimmed.

Here's another couple of videos.

Welding and fabrication projects undertaken, contact me for more information.

Posts: 5,205

Threads: 91

Joined: Dec 2011

Reputation:

83

Location: Oxfordshire/Cornwall

Car Model/Spec: Moonstone DT/Volvo V50

Thanks: 2

Given 41 thank(s) in 41 post(s)

That sounds like ALL of the valves jammed down when you start it...

There's literally NO compression there it sounds like to me...

(16-05-2016, 10:45 AM)Toms306 Wrote: Oh I don't care about the stripped threads lol, that's easily solved by hammering the bolt in.  Nanstone GTD5 GT17S - XUD9TE

Volvo V50 D5 R-Design SE Sport - Daily cruise wagon.

|

![[Image: signature_zps1a02ba79.jpg]](http://i1128.photobucket.com/albums/m481/martypellowe/signature_zps1a02ba79.jpg)

![[Image: sigi-2.png]](http://i281.photobucket.com/albums/kk226/darrenjlobb/sigi-2.png)

Lesson learned. Though I reckon it must have been Scott that killed it, he thought he was in a '6 when he had a little play

Lesson learned. Though I reckon it must have been Scott that killed it, he thought he was in a '6 when he had a little play

![[Image: 20A1806D-891D-40FB-BD52-AD519177A607-734...391753.jpg]](http://i35.photobucket.com/albums/d196/mattbush/20A1806D-891D-40FB-BD52-AD519177A607-7340-0000058F46391753.jpg)

That sucks dude

That sucks dude